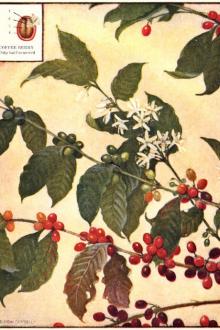

All About Coffee, William H. Ukers [short story to read .txt] 📗

- Author: William H. Ukers

- Performer: -

Book online «All About Coffee, William H. Ukers [short story to read .txt] 📗». Author William H. Ukers

Porto Rico. Here planters favor the wet method of coffee preparation. The crop is gathered from August to December. The coffees are graded as caracollilo (peaberry), primero (hand-picked), segundo (second grade), trillo (low grade).

Nicaragua. The wet method of coffee preparation is mostly favored in Nicaragua. Many of the large plantations are worked by colonies of Americans and Germans who are competent to apply the abundant natural water power of the country to the operation of modern coffee cleaning machinery.

Costa Rica. Costa Rica was one of the first countries of the western world to use coffee cleaning machinery. Marcus Mason, an American mechanical engineer then managing an iron foundry in Costa Rica, invented three machines that would respectively peel off the husk, remove the parchment and pulp, and winnow the light refuse from the beans.

The inventor gave his original demonstration to the planters of San José in 1860, and duplicates were installed on all the large plantations. In the course of the next thirty years, Mason brought out other machines until he had developed a complete line that was largely used on coffee plantations in all parts of the world.

In the Eastern Hemisphere

Modern cleaning machinery and methods of preparation are employed to some extent in the large coffee-producing countries of the eastern hemisphere, and do not differ materially from those of the western.

Arabia. In Arabia the fruit ripens in August or September, and picking continues from then until the last fruits ripen late in the March following. The cherries, as they are picked, are left to dry in the sun on the house-top terrace or on a floor of beaten earth. When they have become partly dry, they are hulled between two small stones, one of which is stationary, while the other is worked by the hand power of two men who rotate it quickly. Further drying of the hulled berry follows. It is then put into bags of closely woven aloe fiber, lined with matting made of palm leaves. It is next sent to the local market at the foot of the mountain. There, on regular market days, the Turkish or Arabian merchants, or their representatives, buy and dispatch their purchases by camel train to Hodeida or Aden. The principal primary market in recent years has been the city of Beit-el-Fakih.

Coffee Drying Patios, Hacienda Longa-Espana, Venezuela

Coffee Drying Patios, Hacienda Longa-Espana, Venezuela

SUN-DRYING COFFEE AMID SCENES OF RARE TROPICAL BEAUTY

In Aden and Hodeida the bean is submitted to further cleaning by the principal foreign export houses to whom it has come from the mountains in rather dirty condition. Indian women are the sole laborers employed in these cleaning houses. First, the coffee beans are separated from the dry empty husks by tossing the whole into the air from bamboo trays, the workers deftly permitting the husks to fly off while the beans are caught again in the tray. The beans are then surface-cleaned by passing them gently between two very primitive grindstones worked by men. A third process is the complete clearing of the bean from the silver skin, and it is then ready for the final hand picking. Women are called into service again, and they pick out the refuse husks, quaker or black, beans, green or immature beans, white beans, and broken beans, leaving the good beans to be weighed and packed for shipment. The cleaned beans are known as bun safi; the husks become kisher. Some of the poorer beans also are sold, principally to France and to Egypt. Hand-power machinery is used to a slight extent; but mostly the old-fashioned methods hold sway.

Early Guardiola Steam Drier, "El Canida" Plantation, Costa Rica Early Guardiola Steam Drier, "El Canida" Plantation, Costa Rica

Photograph by R.C. Wilhelm.

The Yemen, or Arabian, bale, or package, is unique. It is made up of two fiber wrappers, one inside the other. The inside one is called attal or darouf. It is made from cut and plaited leaves of nakhel douin or narghil, a species of palm. The outer covering, called garair, is a sack made of woven aloe fiber. The Bedouins weave these covers and bring them to the export merchants at Aden and Hodeida. A Mocha bundle contains one, two, or four fiber packages, or bales. When the bundle contains one bale it is known as a half; when it contains two it is known as quarters; and when it contains four it is known as eighths. Arabian coffee for Boston used to be packed in quarters only; for San Francisco and New York, in quarters and eighths. The longberry Abyssinian coffees were formerly packed in quarters only. Since the World War, however, there has been a scarcity of packing materials, and packing in quarters and eighths has stopped. Now, all Mocha, as well as Harar, coffee comes in halfs. A half weighs eighty kilos, or 176 pounds, net—although a few exporters ship "halfs" of 160 pounds.

INDIAN WOMEN CLEANING MOCHA COFFEE IN AN ADEN WAREHOUSE

There are four processes in cleaning Mocha coffee. In order to separate the dried beans from the broken hulls these women (brought over from India) toss the beans in the air, very deftly permitting the empty hulls to fly off, and catch the coffee beans on the bamboo trays. Then the coffee is passed between two primitive grindstones, turned by men. After this grinding process the beans are separated from the crushed outside hulls and the loose silver skins. In the fourth process the Indian women pick out by hand the remaining husks, the quakers, the immature beans, the white beans and the broken beans. Being Mohammedans, their religion does not permit such little vanities as picture posing, which explains why their faces are covered and turned away from the camera.

Abyssinia. Little machinery is used in the preparation of coffee in Abyssinia; none, in preparing the coffee known as Abyssinian, which is the product of wild trees; and only in a few instances in cleaning the Harari coffee, the fruit of cultivated trees. Both classes are raised mostly by natives, who adhere to the old-time dry method of cleaning. In Harar, the coffee is sometimes hulled in a wooden mortar; but for the most part it is sent to the brokers in parchment, and cleaned by primitive hand methods after its arrival in the trading centers.

Angola. In Angola the coffee harvest begins in June, and it is often necessary for the government to lend native soldiers to the planters to aid in harvesting, as the labor supply is insufficient. After picking, the beans are dried in the sun from fourteen to forty days, depending upon the weather. After drying, they are brought to the hulling and winnowing machines. There are now about twenty-four of these machines in the Cazengo and Golungo districts, all manufactured in the United States and giving satisfactory results. They are operated by natives.

A condition adversely affecting the trade has been the low price that Angola coffee commands in European markets. The cost of production per arroba (thirty-three pounds) on the Cazengo plantations is $1.23, while Lisbon market quotations average $1.50, leaving only twenty-seven cents for railway transport to Loanda and ocean freight to Lisbon. It has been unprofitable to ship to other markets on account of the preferential export duties. A part of the product is now shipped to Hamburg, where it is known as the Cazengo brand. Next to Mocha, the Cazengo coffee is the smallest bean that is to be found in the European markets.

Java and Sumatra. The coffee industry in Java and Sumatra, as well as in the other coffee-producing regions of the Dutch East Indies, was begun and fostered under the paternal care of the Dutch government; and for that reason, machine-cleaning has always been a noteworthy factor in the marketing of these coffees. Since the government relinquished its control over the so-called government estates, European operators have maintained the standard of preparation, and have adopted new equipment as it was developed. The majority of estates producing considerable quantities of coffee use the same types of machinery as their competitors in Brazil and other western countries.

In Java, free labor is generally employed; while on the east coast of Sumatra the work is done by contract, the workers usually being bound for three years. In both islands the laborers are mostly Javanese coolies.

Under the contract system, the worker is subject to laws that compel him to work, and prevent him from leaving the estate until the contract period expires. Under the free-labor system, the laborer works as his whims dictate. This forces the estate manager to cater to his workers, and to build up an organization that will hold together.

As an example of the working of the latter system, this outline—by John A. Fowler, United States trade commissioner—of the organization of a leading estate in Java will indicate the general practise in vogue:

The manager of this estate has had full control for twenty years and knows the "adat" (tribal customs) of his people and the individual peculiarities of the leaders. This estate has been described as having one of the most perfect estate organizations in Java. It consists of two divisions of 3,449 bouws (about 6,048 acres in all), of which 2,500 bouws are in rubber and coffee and 550 in sisal; the remainder includes rice fields, timber, nurseries, bamboo, teak, pastures, villages, roads, canals, etc.

The foreign staff is under the supervision of a general manager, and consists of the following personnel: A chief garden assistant of section 1, who has under him four section assistants and a native staff; a chief garden assistant of section 2, who has under him three section assistants, an apprentice assistant, and a native staff; a chief factory assistant, who has under him an assistant machinist, an apprentice assistant, and a native staff; and, finally, a bookkeeper. The term "garden" means the area under cultivation.

The bookkeeper, a man of mixed blood, handles all the general accounting, accumulating the reports sent in by the various assistants. The two chief garden assistants are responsible to the manager for all work outside the factory except the construction of new buildings, which is in charge of the chief factory assistant. The two divisions of the estate are subdivided into seven agricultural sections, each section being in full charge of an assistant. A section may include coffee, rubber, sisal, teak, bamboo, a coagulation station and nurseries. The assistant's duties include the supervision of road building and repairs, building repairs, transportation, paying the labor, and the supervision of section accounts.

The beans are being turned by native Sudanese men and women

Interior of a Modern Coffee Factory in East Java Interior of a Modern Coffee Factory in East Java

Showing pulping machinery and fermentation tanks

PREPARING JAVA COFFEE FOR THE

Comments (0)