BIO-PLASTIC, RAHUL YADAV, PREETI YADAV, V C BRIAN [best motivational books for students .txt] 📗

- Author: RAHUL YADAV, PREETI YADAV, V C BRIAN

Book online «BIO-PLASTIC, RAHUL YADAV, PREETI YADAV, V C BRIAN [best motivational books for students .txt] 📗». Author RAHUL YADAV, PREETI YADAV, V C BRIAN

Bioplastics produced directly by natural or genetically modified organisms: - Poly Hydroxy alkanoates (PHA's) and Poly Hydroxy butyrate (PHB) is the most common polyester produced by certain bacteria processing glucose or starch. The properties of PHA's are dependent and relates upon the composition of monomer unit, the microorganisms used in fermentation, as well as the nature of the carbon source used during the fermentation process. It is a typical highly crystalline thermoplastic PHA are elastomers with low-milting points and a relatively lower degree of crystallinity. A very interesting property of PHA's with respect to food packaging applications is their low water-vapour permeability which is close to that of LDPE. The renewable resource-based plastic has similar properties to polystyrene. PHB resembles isotactic polypropylene (iPP) in relation to melting temperature (175-180°C) and mechanical behaviour. PHBs Tg is around 9°C and the elongation to break of the ultimate which is very important in bulk packaging application especially in flexible intermediate bulk containers and bulk shrink packaging. It has been reported in the literature

that annealing can dramatically improve the mechanical properties of PHB by changing its lamellar morphology while subsequent ageing is prevented to a large extent. Incorporation

of 3HV or 4HB co-monomers produces remarkable changes in the mechanical properties. Stiffness and tensile strength decrease with increase of toughness with increasing fraction of the respective co-monomer. Medium chain length PHAs, unlike PHB or its copolymers, behave as elastomers with crystals therefore, can be regarded as a class of its own with respect to mechanical properties. Elongation to break up to 250-350% has been reported and a Young‟s modulus up to 17 MPa.

Polyamides 11: - PA11 is a biopolymer derived from natural oil. It is also known under the trade name Rilson B commercialized by Arkoma. It is used in high-performance application like automotive fuel lines, pneumatic airbrake tubing and flexible goods means they too have good mechanical properties as they are used in automotive and electrical stuffs.

Broad Range of Bioplastics

Bioplastics made from starch use sorbitol and glycerine which plasticizes the starch into a plastic.

Different amounts of these additives are used to fit the use of the plastic

Bottling, packages, cloth,etc

Similar properties of regular plastic but environmental friendly

Starch can also be fermented into lactic acid to make PLA

Bioplastics derived from fatty acids (oils) can be utilized as a fuel resource

Center for Biocatalysis and Bioprocessing of Macromolecules (CBBM) created a new plastic that degrades in a form similar to diesel.

Thermal Properties

Can exceed stainless steel, which can be utilized in household appliances and mobile devices.

High conductivity increases heat dissipation can be used in electronics

Easy to mold due to lower melting temperat

We showed DARPA that we could make a new plastic from plant oils that has remarkable properties, which includes being tougher and more durable than typical polyethylenes. Additionally, the bioplastic can be placed in a simple container where it is safely broken down to liquid fuel.

—Prof. Gross

Military units generate substantial quantities of packaging waste when engaging in stationary field operations. If we can turn this waste into fuel, we will see a double benefit—we will reduce the amount of waste that we have to remove, and we will reduce the amount of new fuel that we must deliver to the units.

—Khine Latt, program manager for DARPA’s Mobile Integrated Sustainable Energy Recovery program

Polycaprolactones: - It is a biodegradable thermoplastic polymer derived from the chemical synthesis of crude oil. Polycaprolactones has good water, oil, solvent and chlorine resistance. It is mainly in thermoplastic polyurethanes, resins for surface coatings adhesives and synthetic leather and fabrics.

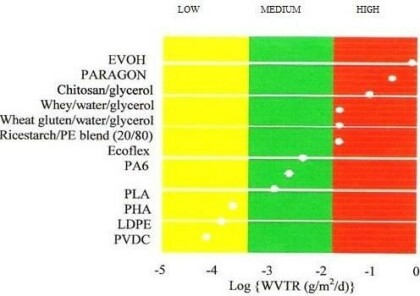

propertiesWater vapour transmittance: While comparing the water vapour transmittance of various biobased materials to conventional plastics it comes out that it is possible to produce biobased materials with water vapour transmittance rates comparable with some conventional plastics. Research are currently focusing on this problem and future biobased materials will be compatible in terms of water vapour barriers with conventional conventional pastic materials known today.

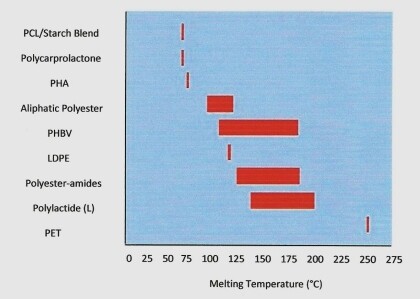

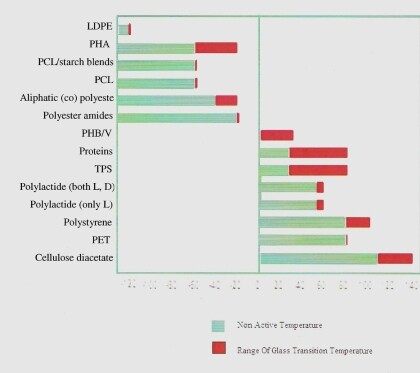

Thermal and mechanical properties: The thermal and mechanical properties of the materials are important for processing and for use of the products derived from these materials. Most biobased polymer materials act in a similar fashion to conventional polymers. This indicates that both polystyrene, polyethylene and PET-like materials can be found among the available biobased polymers.The mechanical properties in terms of modulus and stiffness are not much different compared to conventional polymers.

The modulus of most biobased and petroleum derived polymers can be tailored to meet the required mechanical properties by plasticizing, blending, crosslinking. A polymer like bacterial cellulose could be used in materials to meet special mechanical properties

BULK

PROPERTIES OF BIOPLASTICS (ASTM standard)

Physical properties

Mold shrinkage

0.0125-0.0155 in/in

Density

1.4g/cm³

Apparent viscosity(180ºC, 100 sec¯ ¹)

950 Pa-s

Thermal properties

Melting point

160-165ºC

Heat distortion temperature

143ºC

78ºC

Vicat softening temperature

147ºC

Mechanical properties

Tensile strength

26 MPa(3800psi)

Shrinkage

0.93% caliper

Tensile modulus

3400 MPa(494,000psi)

Mechanical Properties

PROPERTIES OF BIOPLASTICS (ASTM standard)

Physical properties

Mold shrinkage

0.0125-0.0155 in/in

Density

1.4g/cm³

Apparent viscosity(180ºC, 100 sec¯ ¹)

950 Pa-s

Thermal properties

Melting point

160-165ºC

Heat distortion temperature

143ºC

78ºC

Vicat softening temperature

147ºC

Mechanical properties

Tensile strength

26 MPa(3800psi)

Shrinkage

0.93% caliper

Tensile modulus

3400 MPa(494,000psi)

PACKAGING

Packaging is system of preparing goods for transport, distribution storage, retailing and end use. It is means of safe delivery to ultimate consumer in sound condition at economic cost. There are basically three different kind of packages categorized on the basis of use, function, containment of the package.

The first kind of package is unit package, it contain product for one shot is for family requirement, it provides all information related to the product, it also provides aesthetic values and convenience factors to support sales. Intermediate packaging facilitates distribution in the overall marketing system. Bulk, the most important one helps in the complete containment of product or product groups. It facilitates inventory and bulk distribution of package product and also protects them during transportation. To define Bulk Packaging, we can use one of two approaches. The most obvious way is to lay down a basic minimum unit content threshold which is 25 kgs. or 25 liters but this poses certain limitations. The other is to look at the packaging system that what basic function it performs. Using the latter approach, it would be logical to assume that we would want to look at all major applications or packages that are not meant for retail consumption but are only targeted at consumption by manufacturing and processing industries or by organization who are „bulk‟ consumers. In other words, we are looking at packages that contain products which are meant for large-scale or industrial consumption as intermediate inputs for further processing, distribution and re-sale in smaller denominations.

Classification based on basic guidelines there is different bulk packaging systems:

Metal packaging (steel drums and barrels, large cans)

Rigid plastic packaging (Plastic barrels, IBC‟s, large bottles)

Flexible packaging systems (Sacks, woven sacks, FIBC‟s, films for stretch wrapping, shrink wrapping)

Paper-based packaging (corrugated fiberboard, multiwall layer sacks, fiber drums)

Bag-in-box and bag-in-drum systems

Aseptic bulk packaging

Wooden packaging (pallets and cases)

Our primary focus will be on the rigid plastic packaging and flexible packaging systems because they have to be replaced in recent future by bioplastics. The need of replacement for the petroleum based plastic with bioplastics is just because

Producing conventional plastics consumes 65% more energy than producing bioplastic.

Conventional plastic are mostly toxic.

Plastics last a long time and do huge damage to environment. Therefore, plastic is absolutely unsustainable and bioplastic is more sustainable.

Bioplastics saves 30-80% of the greenhouse gas emissions and provide longer shelf-life than normal plastic.

Bulk packaging systems related with conventional plastics are as follows:-

Intermediate bulk containers (IBC): An Intermediate bulk container is a container used for transport and storage of fluids and bulk materials. The construction of the IBC container and the materials used are chosen depending on the application. They are generally cubic in shape and therefore can transport more material in the same volume than cylindrically shaped containers and far more may be shipped in the same space if packaged in consumer quantities. IBCs range in size but are generally between 700 and 2,000 mm or 1,168 to 1,321mm in height. IBCs may ship and store Bulk chemicals including hazardous materials if the IBC is proven suitable. The plastic used in the manufacturing of IBC‟s are basically polyethylene, polypropylene these are plastics are used because they have lower impact strength, high tensile strength, High compressive strength, excellent dielectric properties, resists to alkalis and acids, resists stress cracking, retains stiffness, low moisture absorption, non- toxic, non-staining, easily fabricated, and high heat resistance.

ASTM or UL test

Property

LDPE

HDPE

POLYPROPYLENE

NYLON

PVC

PHYSICAL

D792

Density (g/cm³)

(lb/in³)

0.033

0.92

0.035

0.95

1.22-1.23

1.12 - 1.14

0.051

1.41

D570

Water Absorption, 24 hrs (%)

<0.01

0

0.09-0.1

2.9

0

MECHANICAL

D638

Tensile Strength (psi)

1,800-2,200

4,600

58 - 104

9.4

7500

D638

Tensile Modulus (psi)

-

-

195,000

411,000

D638

Tensile Elongation Yield (%)

at

600

900

12

25

D790

Flexural Strength (psi)

-

-

72-15

NO YEILD

12800

D790

Flexural Modulus (psi)

-

200,000

6555-6900

1.5

481000

D695

Compressive Strength (psi)

-

-

7,000

D695

Compressive Modulus (psi)

-

-

-

D785

Hardness, Shore D

D41-D50

D69

92R

104(R)

115(R)

D256

IZOD Notched Impact (ft-lb/in)

No Break

3

1.9

2.2

1.0

THERMAL

D696

Coefficient of Linear Thermal Expansion (x 10-5 in./in./°F)

3

6

6.2

4

6.1

D648

Heat Deflection Temp

120 / 105 / 36

48

170 / 150 / 40

76

210

125/52

/

99

340

176/80

(°F / °C)

at 66 psi

at 264 psi

D3418

Approx. Melting Temperature (°F / °C)

230 / 110

260 / 125

327 / 164

-

-

Max Operating Temp (°F

/ °C)

160 / 71

180 / 82

180 / 82

175

140/60

C177

Thermal Conductivity

-

-

0.76-0.81

0.90

(BTU-in/ft²-hr-°F)

(x 10-4 cal/cm-sec-°C)

-

-

2.6-2.8

3.1

UL94

Flammability Rating

n.r.

n.r.

H-B

H-B

V-O

ELECTRICAL

D149

Dielectric Strength (V/mil) short time, 1/8" thick

460-700

450-500

500-660

544

D150

Dielectric Constant at 1 kHz

2.25-2.30

2.30-2.35

2.25

3.7

3.2

D150

Dissipation Factor at 1 kHz

0.0002

0.0002

0.0005-0.0008

0.12

.0096

D257

Volume Resistivity (ohm-cm) at 50% RH

1015

1015

8.5×1014

10-12

5.4 x 1015

D495

Arc Resistance (sec)

135-160

200-250

160

Plastics

Water vapour

transmission rate g/m²,38ºC, 90% RH

Gas transmission rate cc/m², 24h/atm at 25ºc

Heat seal rate, ºC

O²

CO²

LDPE

18.6

7750

41850

158-176

HDPE

4.6-100

2868

8990

162-169

Polypropylene

6.2-100

2325-

3720

7750

170-188

PVC

60

124-465

310-465

158-176

Nylon

388

40.3

155-186

176-220

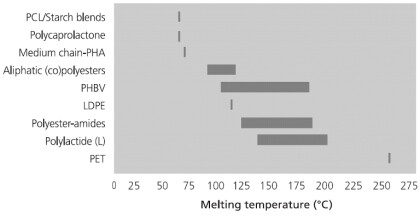

Thermal properties: Melting temperature

Biopolymers comparable with conventional plastics

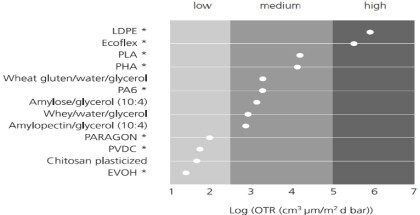

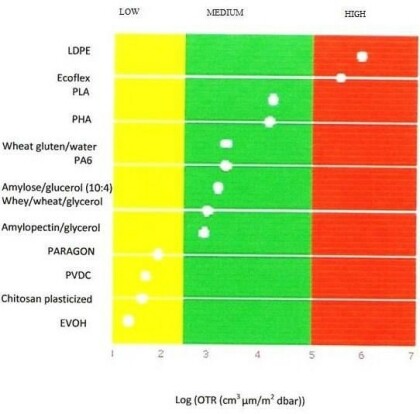

Oxygen transmission rate

Biopolymers in the midfield

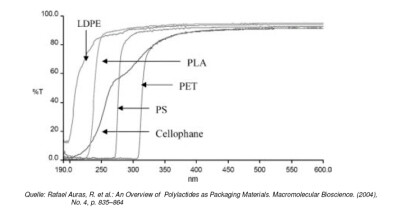

Transmission of UV-light

Gas barrier properties: In most packaging applications the gas mixture inside the package consists of carbon dioxide, oxygen and nitrogen or combinations. Biobased materials have quite same oxygen permeability that of conventional mineral-oil-based materials and it is possible to select from a range of barriers among the present biobased materials. The conventional approach to introduce high-barrier films for packaging of food is to use multi-layers of different films in order to obtain the required properties. A laminate that is often used in packaging consists of an layer of EVOH or PA6 combined with LDPE for mechanical strength and the excellent sealing properties. A similar multi-layer approach for biobased materials may be used to produce materials with the required properties. Starch-based materials could provide cheap alternatives to presently available gas barrier materials like EVOH and PA6 and an equivalent biobased laminate would be an outer- layer of plasticized chitosan, a protein or starch-derived film combined with PLA or PHA. PLA and PHA will protect the moisture-sensitive-gas-barrier made of polysaccharide and protein. Developments have made it possible to improve water vapour and gas properties of biobased materials many-fold by using plasma deposition of glass- like SiOx coatings on biobased materials or the production of nano-composites out of a natural polymer.

In general, the oxygen and other gases permeability of a specific material are closely interrelated, petroleum based polymers have a fixed ratio between the oxygen and carbon dioxide permeabilities. This relation is also observed for biobased materials. However, for some biobased materials,like PLA and starch, the permeability of carbon dioxide in comparison to oxygen is much higher than for petroleum based plastics.

Gas barriers, humidity and microbial growth

As many of these biobased materials are hydrophilic in nature therefore their gas barrier properties are very much dependent on the humidity conditions for the measurements and its gas permeability may increase many times with when increase in humidity. Same is the phenomenon with conventional polymers. Gas barriers based on PLA and PHA is not expected to be more dependent on humidity. According to the study microbial contamination levels of packages made from conventional and biobased materials are relatively below the standard of 1 organism/cm2. A microbial study of cellulose triacetate, a type of bioplastic shows that after years of storage under ambient conditions mostly Pseudomonas bacteria is found in the film. Different tests for fungal growth (ASTM G21-96, G22-76, G21-70) has been conducted on the bioplastics, after many years of storage it was found that a low growth of selected food related fungi like Penicillium ocured in the same.

.

.

Water vapour transmittance: While comparing the water vapour transmittance of various biobased materials to conventional plastics it comes out that it is possible to produce biobased materials with water vapour transmittance rates comparable with some conventional plastics. Research are currently focusing on this problem and future biobased materials will be compatible in terms of water vapour barriers with conventional conventional pastic materials known today.

Thermal and mechanical properties: The thermal and mechanical properties of the materials are important for processing and for use of the products derived from these materials. Most biobased polymer materials act in a similar fashion to conventional polymers. This indicates that both polystyrene, polyethylene and PET-like materials can be found among the available biobased polymers.The mechanical properties in terms of modulus and stiffness are not much different compared to conventional polymers.

The modulus of most biobased and petroleum derived polymers can be tailored to meet the required mechanical properties by plasticizing, blending, crosslinking. A polymer like bacterial cellulose could be used in materials to meet special mechanical properties.

The manufacturing processes which can be used for a bioplastic bulk packaging are extrusion, co-extrusion, blow moulding, injection blow moulding and thermoforming. Bioplastics can be processed in all of these process to a potential bulk package.

PROPERTIES OF BIOPLASTICS (ASTM standard)

Physical properties

Mold shrinkage

0.0125-0.0155 in/in

Density

1.4g/cm³

Apparent viscosity(180ºC, 100 sec¯ ¹)

950 Pa-s

Thermal properties

Melting point

160-165ºC

Heat distortion temperature

143ºC

78ºC

Vicat softening temperature

147ºC

Mechanical properties

Tensile strength

26 MPa(3800psi)

Shrinkage

0.93% caliper

Tensile modulus

3400 MPa(494,000psi)

Polymer

Comments (0)